Chemical and pharmaceutical industry

SPECK supplies pumps and systems for the chemical and pharmaceutical industries. We offer solutions for hygienic operation and operational safety for critical processes. We are happy to support you in the planning of new systems as well as in the retrofitting of existing pumps and systems. SPECK products are developed and manufactured in Germany.

Areas of application:

- General water supply for industrial companies

- Drinking water separation for laboratory processes

- Drinking water supply / drinking water separation for emergency and eye showers

- Tank systems, e.g. delivery of liquid gas

- Heating or cooling processes

- Distillation and separation of liquids

- Condensate recovery, e.g. solvents

- Bulk drying, e.g. washing powder, fertilizer, salts, plastic granulate, etc.

- Temperature control of chemical processes

- Conveying aggressive, highly flammable and toxic media

- Systems with system pressures up to 100 bar

- General processes such as degassing, extraction, suction and vacuum cooking

Your advantages:

- Operational safety

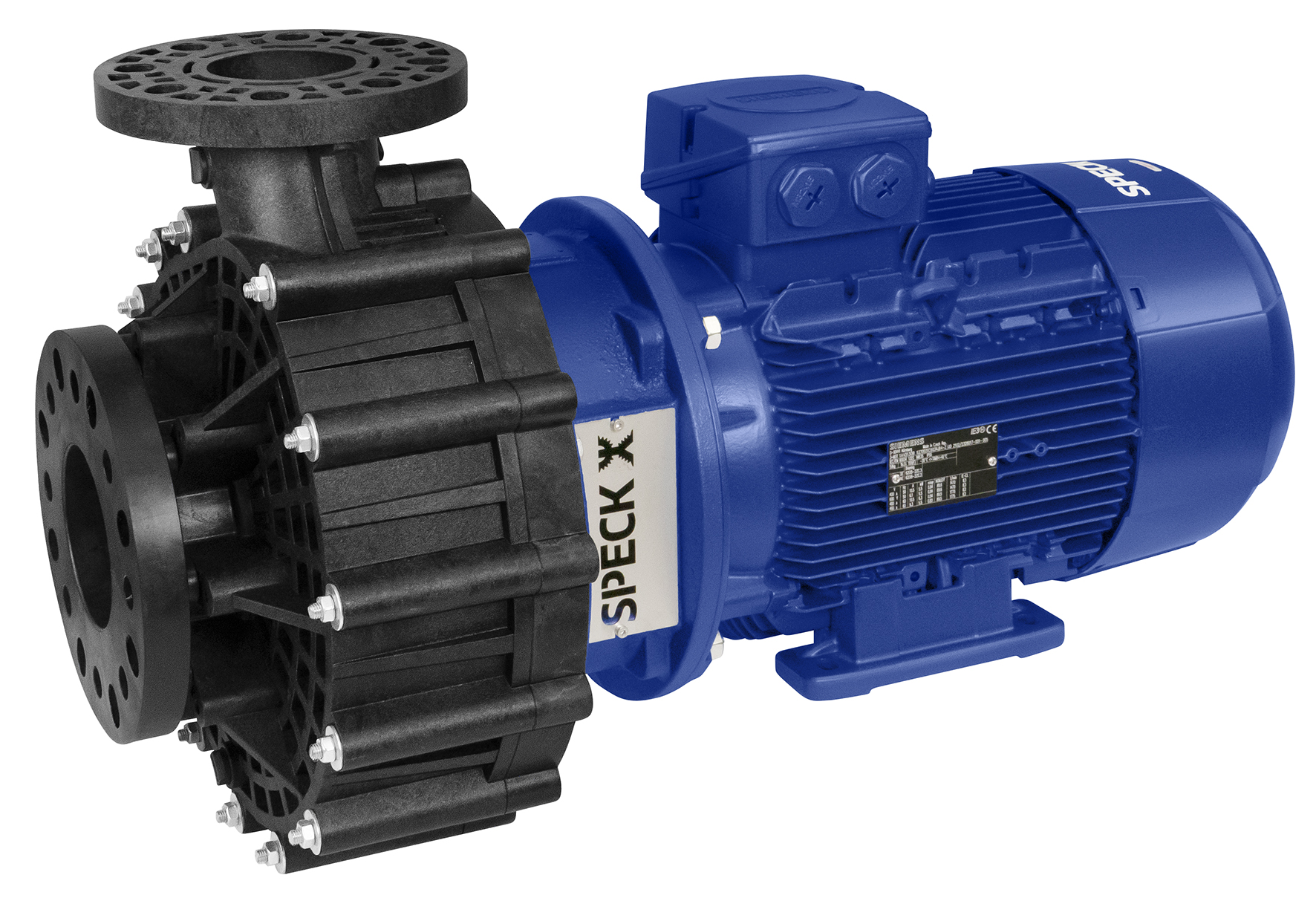

- Use of media-resistant materials

- Use of modern and efficient drives

- Large selection of sealless pumps

- Hygienic drinking water separation

- Safety, health and environmental protection

- Energy saving

- Certifications and documentation

Products for your application:

- Drinking water separation stations

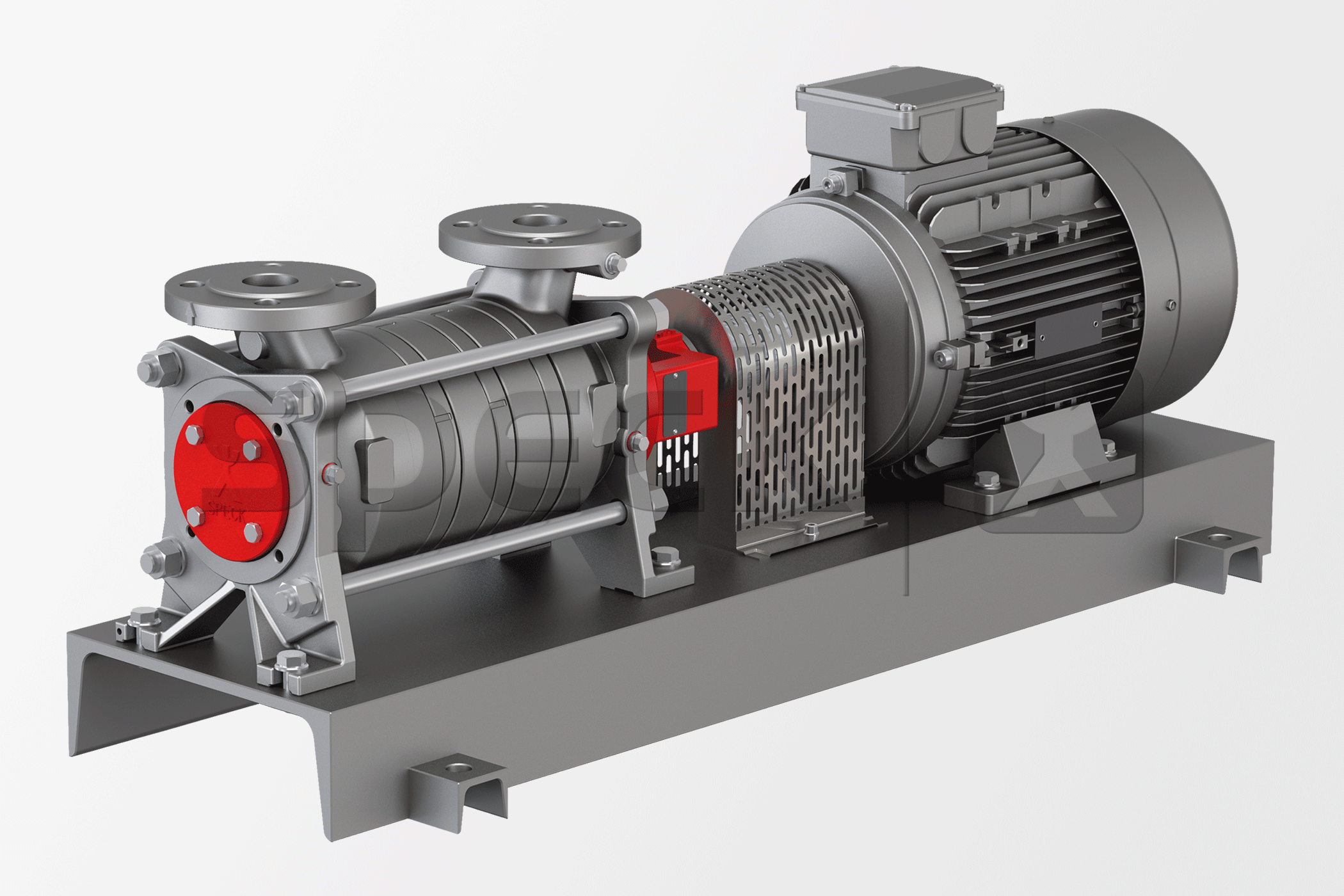

- Pressure boosting systems

- High pressure pumps

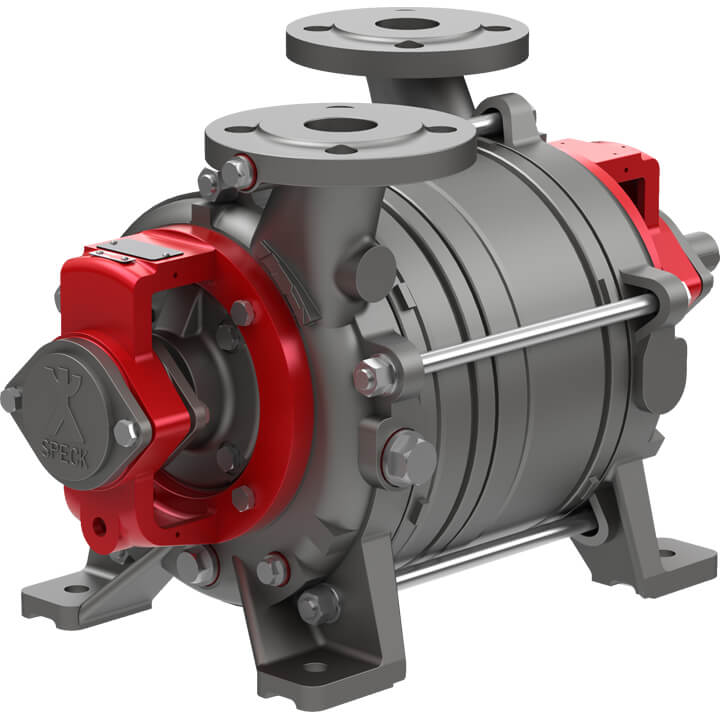

- Vacuum pumps

- Side channel pumps

- Small centrifugal pumps

- Norm Block pumps

- Vertical stage centrifugal pumps

- Horizontal centrifugal pumps

Limits of use:

- Temperature: cold down to -100 °C, heat up to +350 °C

- Volume: Suction capacity up to 1600 m³/h, flow rate up to 960 m³/h

- Pressure: Suction pressure 33 mbar, delivery pressure up to 1200 bar

Motor technologies:

- IE3 / IE4 asynchronous motors

- Permanent magnet motors IE5

- Synchronous motors IE5

Certifications:

- ATEX

- Conformity according to TA-Luft

Materials:

- Various plastics, gray cast iron, ductile cast iron, brass, bronze, stainless steel, aluminum, duplex, superduplex, Hastelloy

Sealing types:

- Mechanical seal

- Magnetic coupling

- Can technology

Sealing materials:

- NBR, EPDM, Viton, Kalrez, graphite, Teflon