Food & beverage industry

SPECK supplies pumps and systems for the food and beverage industry. Thanks to our many years of experience, we know the processes and offer products for hygienic operation and operational reliability in continuous use. We supply pumps and solutions to original equipment manufacturers, provide support during the project and development phase in selecting the right pump and offer customized solutions for industrial companies. Our products are developed and manufactured in Germany.

Areas of application:

- Drinking water separation for laboratories

- Drinking water separation for farms

- Drinking water treatment in osmosis systems

- High pressure cleaning

- Hot water supply in food processing companies

- Cooling water supply

- Bottling of beer and mineral water

- Central vacuum generation

- Decentralized vacuum generation for gentle brewing processes

- General processes such as degassing, extraction, suction

- Conveying and circulating beverages, milk, whey, brine and curing brine

- Conveying milk and whey in agricultural feeders

Your advantages:

- Hygienic drinking water separation

- Safety, health and environmental protection

- Modern drive technologies to reduce the CO2 footprint

- Saving energy in water distribution

- Smallest pump dimensions

- Wear-free, magnetically coupled pumps

- Modern sealing technologies for greater process reliability

- CIP-capable pumps

Products for your application:

- Drinking water separation stations

- Pressure boosting systems

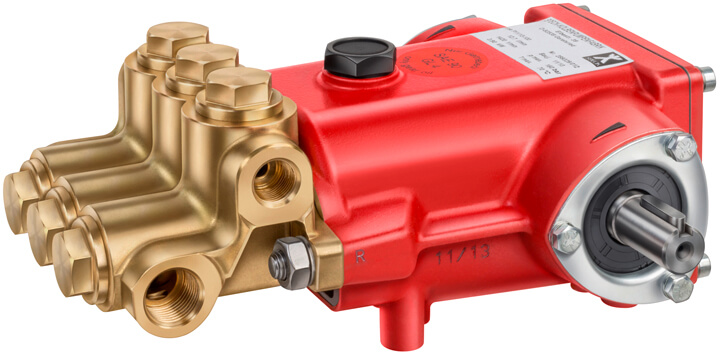

- High-pressure pumps / high-pressure systems

- Vacuum pumps

- Side channel pumps

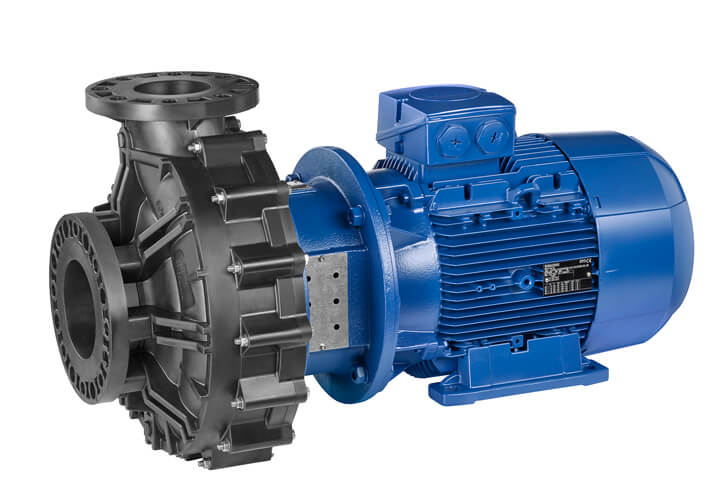

- Small centrifugal pumps

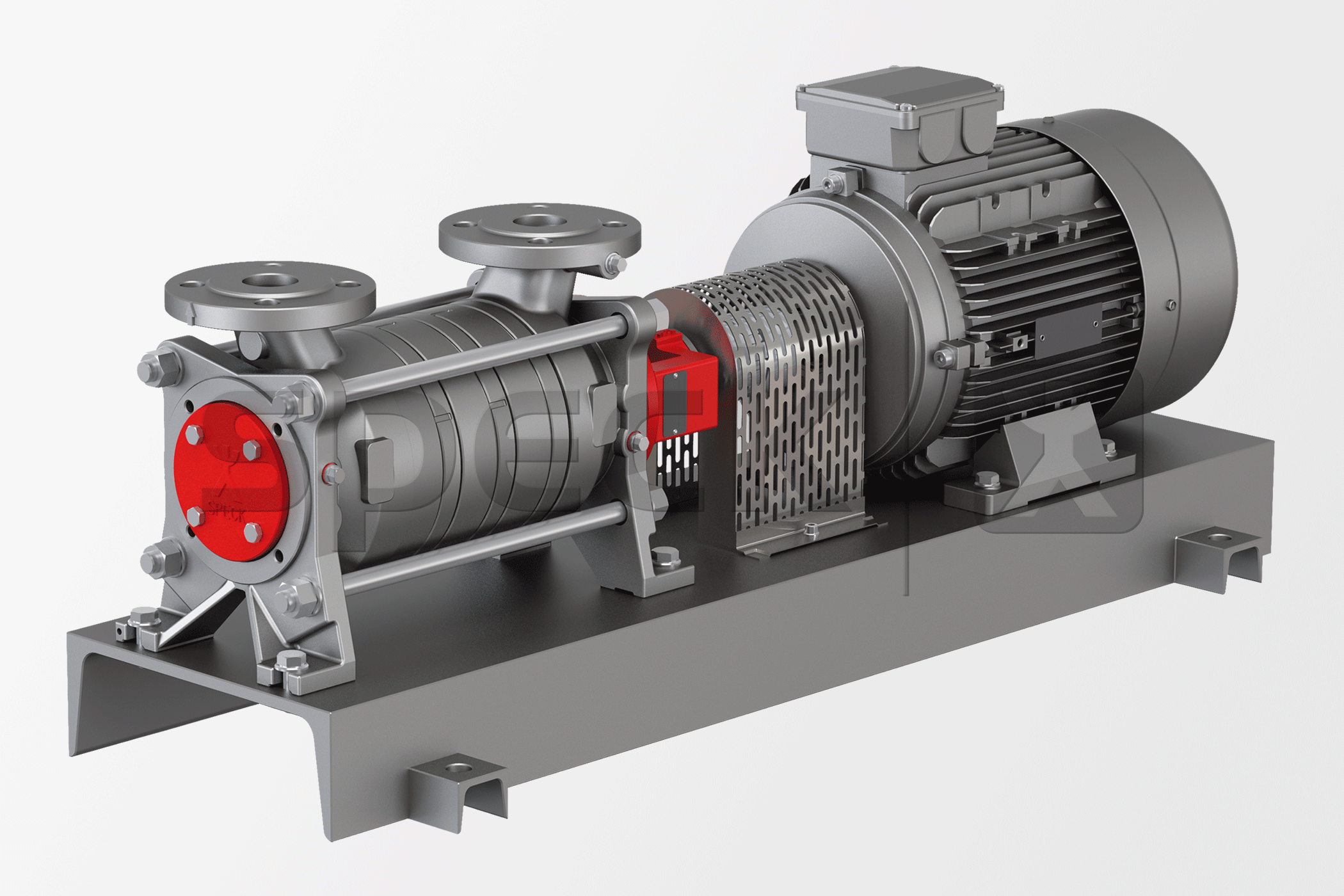

- Norm Block pumps

- Vertical stage centrifugal pumps

- Horizontal centrifugal pumps

- Submersible pumps

Limits of use:

- Temperature: cold down to -100 °C, heat up to +350 °C

- Volume: Suction capacity up to 1600 m³/h, flow rate up to 960 m³/h

- Pressure: Suction pressure 33 mbar, delivery pressure up to 1200 bar

Motor technologies:

- Asynchronous motors IE3/ IE4

- Permanent magnet motors IE5

- Synchronous motors IE5

Controls:

- Motorized controls

- Frequency inverters preconfigured for the product

- Complete control systems for single and multi-pump systems

Materials:

- Various plastics, gray cast iron, ductile cast iron, brass, bronze, stainless steel, aluminum, duplex, superduplex, Hastelloy

Sealing types:

- Mechanical seal

- Magnetic coupling

- Canned motors

Sealing materials:

- NBR, EPDM, Viton, Kalrez, graphite, Teflon